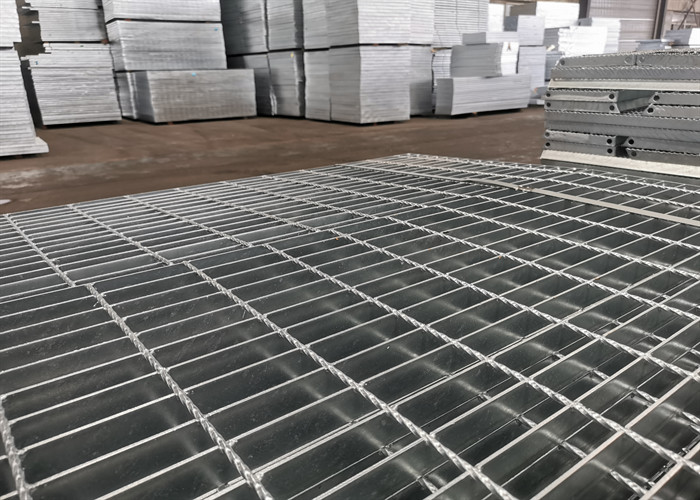

Chemical Plant Galvanised Floor Grating Anti Skid Pressure

Resistance Welding

Chemical Plant Maintenance Platform Anti-Skid Platform Steel

Grating

Platform Steel Grating Product Introduction

Platform Steel Grating Is the most commonly used steel grid plate

in the most widely used products, steel grid plate welded after

galvanized, not only beautiful appearance, but also can play a good

role in anticorrosive and rust prevention, prolong the service

life, by the majority of customers.

Hot dip galvanized steel grid plate is characterized by: high

strength, light structure;The solid grid pressure welding structure

makes it has the characteristics of high load bearing, light

structure, easy to hoisting and so on;Beautiful appearance,

durable.

Acid and alkali corrosion ability: in the range of pH 6 to pH 12.5,

the zinc layer surface formed a stable protective film, good

corrosion resistance.

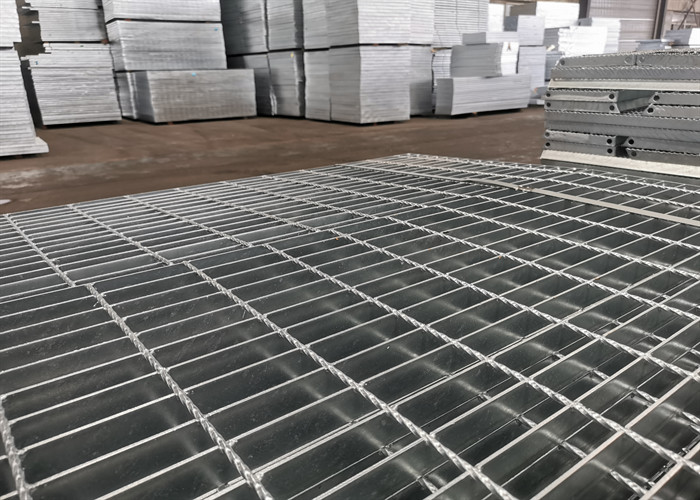

Platform Steel Grating Product Specifications

| Product name | Steel Grating |

| Finish | Hot galvanized ,Paint,Untreatment (black/slef color) |

| Weld way | Automatic pressure resistance welding |

| Usage | Industrial platform, Corridor laying, Ditch cover plate, Fence, etc |

| Thickness | 3-10mm |

| Bearing bar pitch | 20mm 30mm 40mm |

| Cross bar pitch | 50mm 100mm |

| Style | Plain sheet,Serrated sheet,I type shee |

Rod spacing: 50, 100mm.

Bar size: commonly used 6x6mm twisted square steel, small

specification steel grid to take 5X5mm twisted square steel,

stainless steel commonly used diameter of 5mm round steel.

Flat steel size: commonly used 20×3mm to 75×6mm and other

specifications.

Flat steel spacing: 30mm, 40mm, 60mm.

Surface treatment: G for hot dip zinc, P for dip paint.

Platform Steel Grating Product Application

The application scope of platform steel grid, general factories,

coal mines, offshore drilling platforms, oil refineries, vinyl

plants, power plants, coal mines, power stations, workshops, ships

and all kinds of natural gas chemical platform can be selected,

beautiful and durable, easy installation, is a new type of building

products to update.By welding Angle iron and hinge on the frame of

the steel grid on the platform, many special occasions can be used,

such as the cover plate of the air outlet and the trench.

Platform Steel Grating Product Advantages

1. Hot dip galvanized steel grille: it is through the physical

reverse so that the inserted grille plate is coated with zinc

layer, with beautiful products, acid resistance, alkali resistance,

corrosion resistance, rust prevention, long service life and other

characteristics, suitable for outdoor.

2. Electric galvanized steel grille: it is made by chemical

reaction to form a thin layer of zinc through the plasma exchange

of the platform steel grille plate, suitable for dry environment,

such as indoor, etc.

3. Spray-painted steel grille plate: corrosion resistance medium,

moderate price, color can be optional and other characteristics.

4. Don't handle steel grille plate: cheap price, suitable for

indoor and dry environment, but in wet and rainy environment is

easy to rust.

Platform Steel Grating Installation Method

Steel grid plate in the welding installation is generally fixed at

the four corners of the steel grid, using the form of pull welding

welding, weld length shall not be less than 20mm, height shall not

be less than 3mm, for a single large area of steel grid plate,

should be appropriate to increase the welding position, in order to

increase the rigidity of the steel grid.

The welding position is better on the inside of the first bearing

flat steel, so that the welded steel grid looks beautiful, safe and

reliable.

Because when welding steel plate damage on the surface of the

coating, advice immediately after the completion of the steel plate

welding to anti-corrosion coating anticorrosive paint, due to the

spraying antirust paint adhesion is far worse than at the beginning

of anticorrosive coating adhesion, so steel case board installation

is complete to regularly check whether antirust paint falls off, in

the event of loss, carries on polishing processing should

immediately,

After finishing the polishing and then spraying, this will greatly

extend the service life of the steel plate, the welding will not

corrode, but also relatively increase the safety factor.

The steel grid plate installed by welding is suitable for one-time

fixing and does not need to be disassembled twice. The welding

fixing cost is low and the installation speed is fast, so it is a

common installation method.

Package delivery:

Delivery when will we have a professional inspectors to check the

quality of the product is unqualified, such as qualified will paste

the qualified product certificate, and then fixed by shipping

packaging, packaging with the steel plate on the metal tray, and

then fixed with metal packing tape, finally wrapped by plastic film

packaging, general each pallet packing 1-2 tons of cargo, in order

to convenient for unloading and storage after the arrival of the

goods. The unqualified products will be recalled by our quality

inspector.